Foundry process

Sand casting

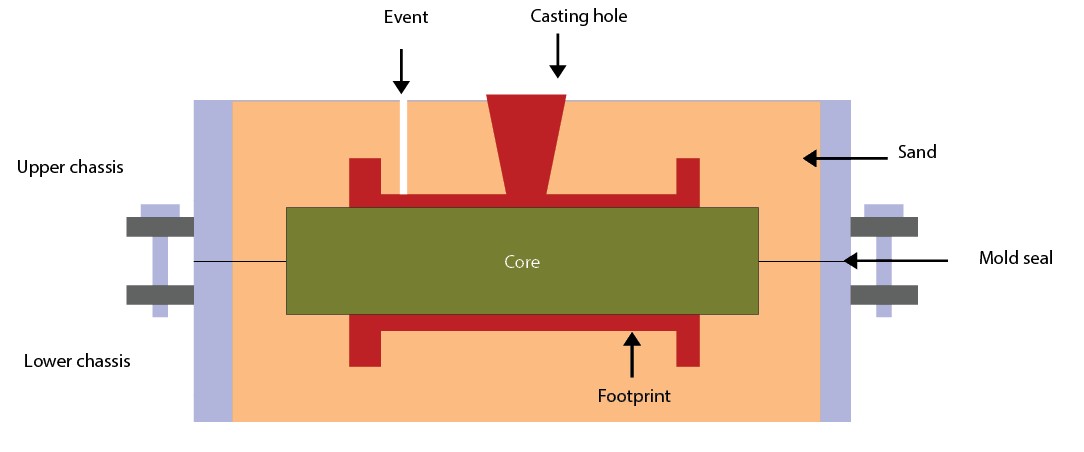

Sand moulding consists in making an impression in the sand from a piece-shaped model. Two metal frames, perfectly fitting, serve to maintain the sand used to take the impression of the model.

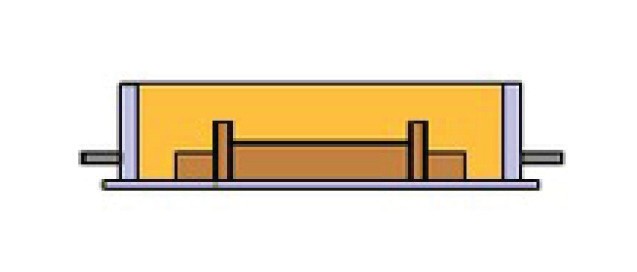

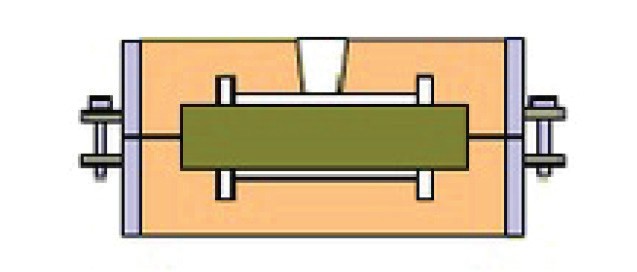

The founder prepares the lower part of the mould, the half-model is covered with sand.

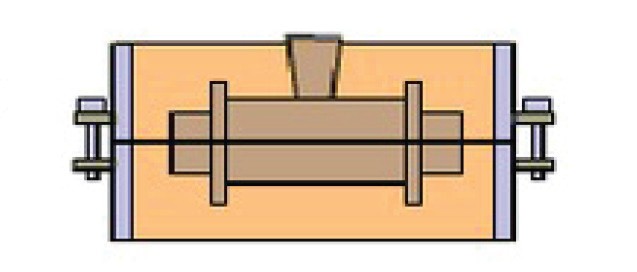

For the upper part of the mould, the founder adjusts the second part of the model on the first. He adds the casting channel model and then fills the frame with sand.

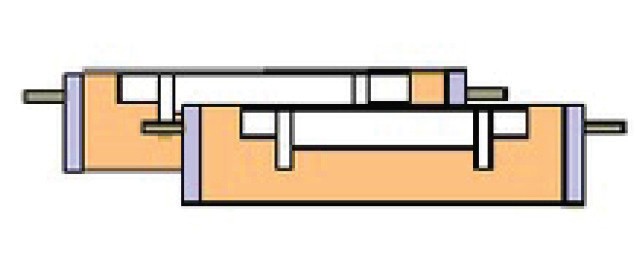

The core is placed on its spans,then the mould is closed.

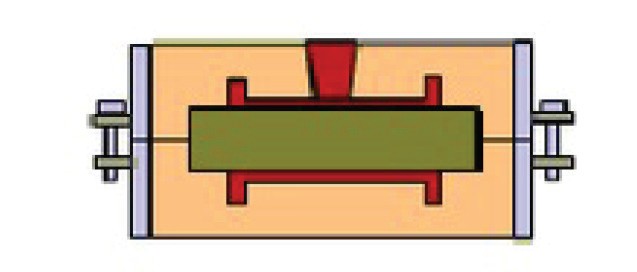

Then, the founder proceeds to cast the molten alloy in the mould.

Once the part cooled down, the sand mould is destroyed and the sand is treated. The workpiece is separated by sawing pouring channel and vents. Then, grinding is performed to remove burrs.

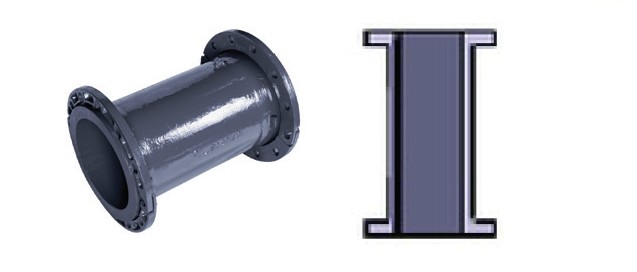

The foundry blank is ready for machining its functional surfaces.